Steel structure workshop build in South Sudan

Steel structure workshop build in South Sudan

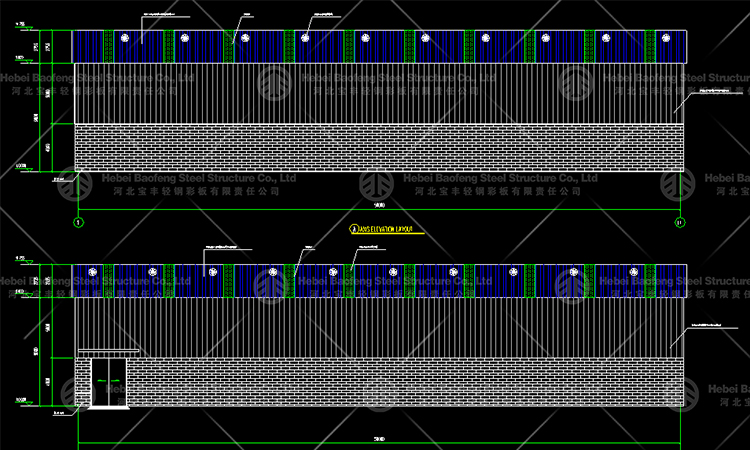

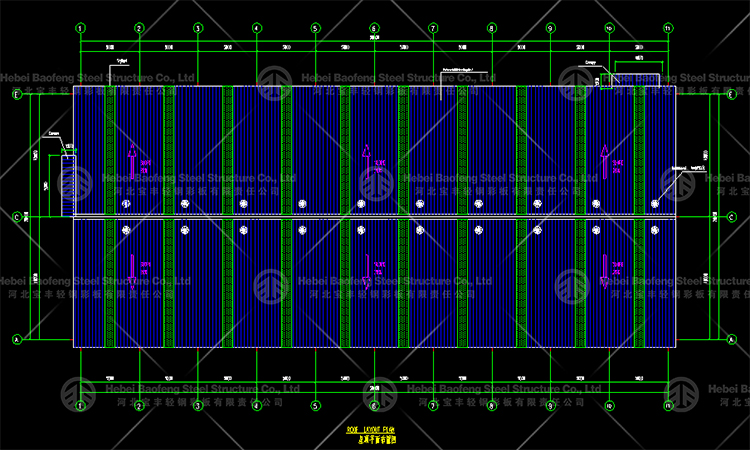

Building size: 50m (L) x 20m (W) x 9m (H).

The local wind load is 0.3kn/m2

Live load: 0.3kn/m2

Dead load: 0.15kn/m2

Technical Parameters

1. Main Structure: Q235B Welded H Section Beam

2. Roof Purlin and Wall Girt: Galvanized C Section steel

3. Roof panel : V840 (0.4mm) single board

4. Tie Rod: Hot-dip galvanized Circular Steel Tube

5. Brace: Round Bar

6. Column Cross Bracing and Roof Bracing: Galvanized Steel Rod

7. Fly Brace: Angle Steel

8.Door: 4m x 4.5m and 3m x 4m, sandwich sliding door

9.Connecting: High Strength Bolts

The advantages of prefab steel structure building :

Wide using range : using for a wide range of project needs – from commercial (Car Shed ,Exhibition Hall ) to agricultural (metal barns, storage sheds) to industrial (Workshop, equipment storage).

Fast Construction : All the steel structure components are prefabricated , finished fabricated and painted in factory then delivery to site for construction , save construction time .

Lower labor cost : All the prefabricated steel structure just need bolt connected on site for Primary and secondary structure ,without secondary welding on site , save manpower and reduce the labor cost .

Appearance good and practical: Steel Warehouse Building has a variety of colors to choose , the wall also can use other materials, and therefore has more flexibility.