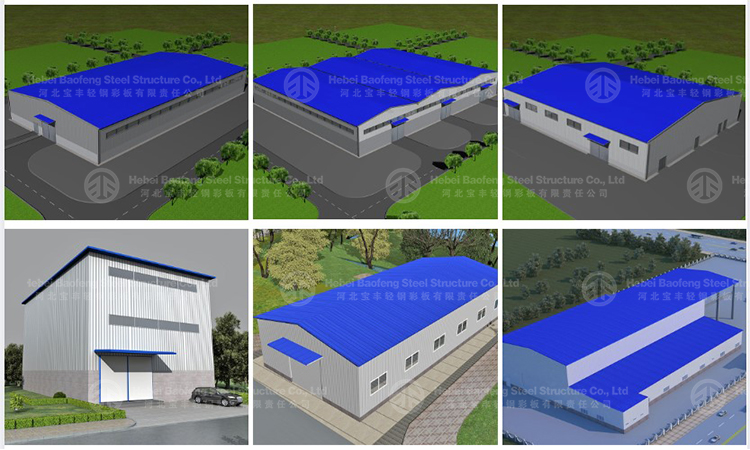

Designed for durability and efficiency, our steel structure warehouses offer robust construction and easy installation, making them ideal for various storage needs.

Item No.:

gg-10-cmj-GPayment:

T/T & L/CProduct origin:

Hebei, ChinaShipping port:

TianjinLead Time:

about 30 daysPrice:

30-50 usd/sqm

Product Description

Steel structure building is a product that can be designed according to the different needs of each person.

|

Size |

Customized |

|

Application |

Steel Structure Warehouse/Workshop/Hanger/Shed/ Sports Stadium |

|

Main Frame |

H section steel |

|

Purlin |

C,Z purlin |

|

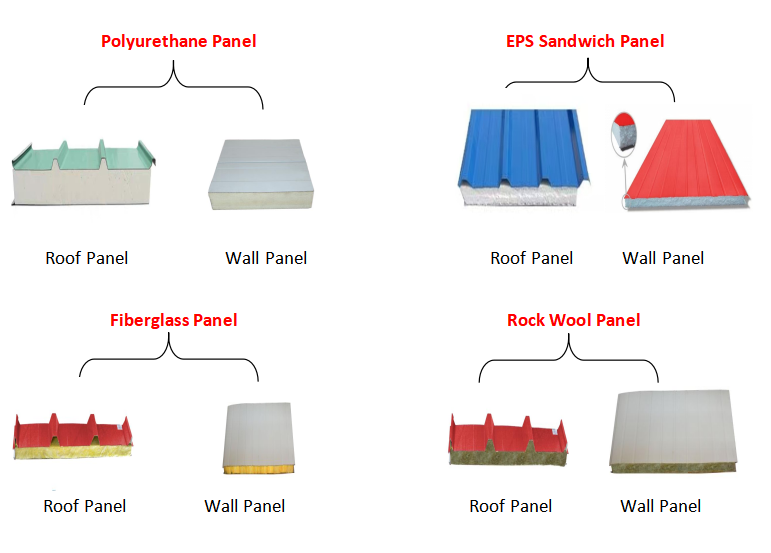

Roof and Wall Material |

EPS/rock wool/fiberglass wool/PU sandwich panel,corrugated sheet |

|

Surface Treatment |

Hot-dip galvanized,electric galvanization,paint |

|

Colour |

Customized |

|

Performance |

Heat-insulation,Fire proof,Sound proof,recyclable |

Advantages

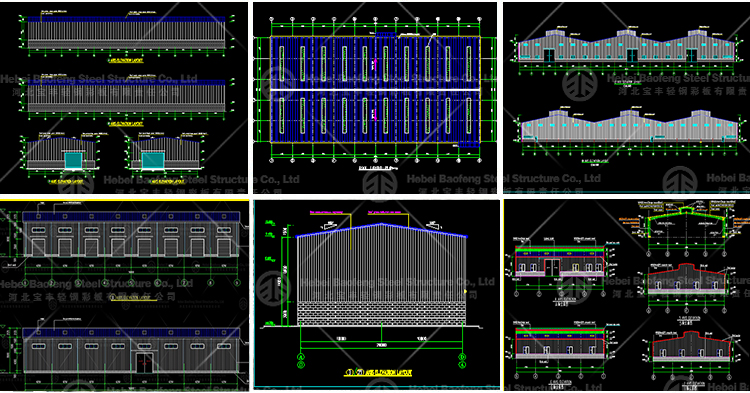

(1) Free design and architectural drawings provided;

(2) Durability, easy maintenance, designed life span for 50 years;

(3) Fast and easy assemble, online installation guidance provided;

(4) Elaborate and strong design, high wind resistance performance;

(5) Thermal and noise insulation, water proof and fire prevention.

Usage

Steel structure buildings are versatile and widely used across various sectors. In industry, they provide durable and spacious facilities for manufacturing and warehousing. In agriculture, they serve as robust structures for livestock housing, storage, and greenhouses. For commercial purposes, steel buildings offer flexible designs for retail spaces, offices, and event venues, ensuring safety and longevity.

(1)Industrial Uses:

(2)Agricultural Uses:

(3)Commercial use:

Production Process

Materials of Wall and Roof

Drawings

1) Customized design is welcomed.

2) We have an excellent design team. According to the requirements of different projects and clients, we will supply different designs and steel products. In order to give you an exact quotation and drawings, please let us know the following information. We will quote for you promptly.

Production Certification

Customer Photos

If you are looking for your next steel warehouse, then Hebei Baofeng has you covered! We offer prefabricated and customized steel building packages and will work with you to ensure your building design matches your organization’s specific needs.

If you’d like to learn more about available products and services, then feel free to contact us at your convenience. We’re here to answer your questions and help select the optimal steel building design for you. Pls contact us.

Previous :

Long span steel structure workshop steel metal building in KenyaNext :

Large span steel structure warehouse construction material for wholesaleIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Modern design steel frame building prefabricated construction steel structure material warehouse for sale Read More

Large span weld H beam prefabricated steel structure workshop made in China Read More

Prefabricated light steel structure storage warehouse buildings made in China Read More

Prefabricated luxury living expandable container house Read More

Customized Steel Structure Two-story chicken coop exported to the Philippines Read More