Metal steel structure frame building manufacturer

Item No.:

Gg-130Payment:

T/T & L/CProduct origin:

Hebei, ChinaShipping port:

TianjinLead Time:

about 30 daysPrice:

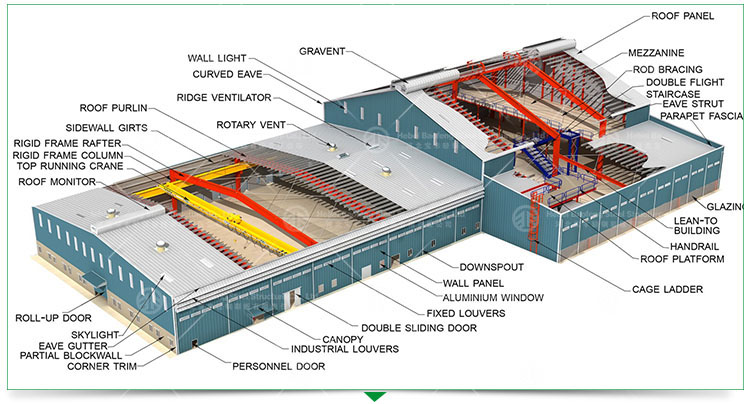

30-50 usd/sqmProduct Description

|

Size |

Customized |

|

Application |

Steel Structure Warehouse/Workshop/Hanger/Shed/ Sports Stadium |

|

Main Frame |

H section steel |

|

Purlin |

C,Z purlin |

|

Roof and Wall Material |

EPS/rock wool/fiberglass wool/PU sandwich panel,corrugated sheet |

|

Surface Treatment |

Hot-dip galvanized,electric galvanization,paint |

|

Colour |

customized |

|

Performance |

Heat-insulation,Fire proof,Sound proof,recyclable |

Production process

1. Pre-production meeting: Discuss project requirements and execution standards, ensuring customer’s demands are accurately forwarded to the production line.

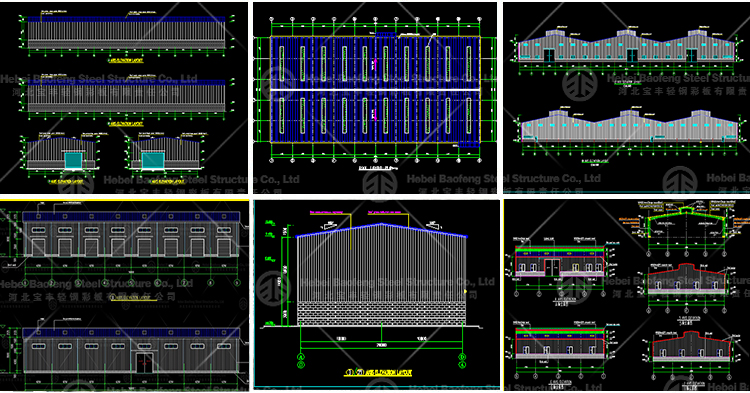

2. Production drawings: With quality requirements and process standards.

3. Raw Material Inspection: Rigorous inspection of raw materials ensures qualified products entering the factory.

4. CNC flame cutting and slicing:High Precision and high production efficiency make the steel cutting amount per day up to 150-200 tons.

5. H-Beam Spot Welding and Assembly: Assembled welded and corrected in a streamlined process with a production rate of approximately 25 meters per hour.

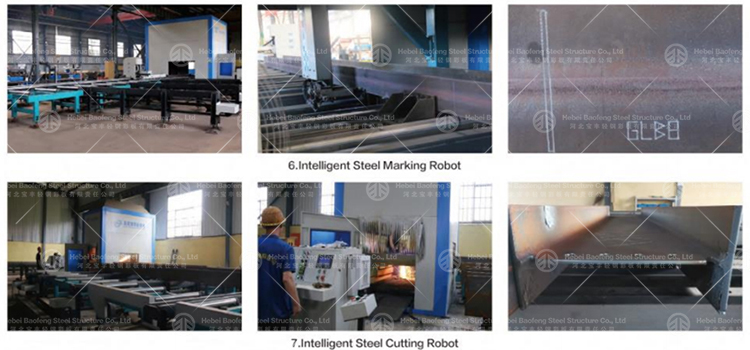

6. Intelligent Steel Marking Robot: Smart operation for precise line marking.

7. Intelligent Steel Cutting Robot: Infrared ray scans marking, accurate cutting. Perfect finish, efficient cuts up to 50 tons.

8. Small Plates Fabrication: Automated CNC machines, ensuring high-speed, accurate drilling to guarantee error-free installation.

9. Assembly: Connected plates are assembled and welded on H beam, Cross work maximize welding efficiency.

10. Shot Blasting: Sa 2.5 grade clean rust and enhance coating adhesion, extend life usage.

11. Semi-Finished Product Inspection: 100% quality inspection to ensure product compliance.

12. Painting: Four coats of paint , ensuring a smooth, bubble-free, crack-free, and uniform surface finish.

13. Product Coding: Every steel structure part is clearly coded according to installation drawings, ensuring smooth installation.

14. C-Steel Production: CNC programming ensure smooth, high-efficiency production, yielding 5,000 meters daily.

15. Single Panel Production: Six machines produce 10,000 meters daily, high efficiency.

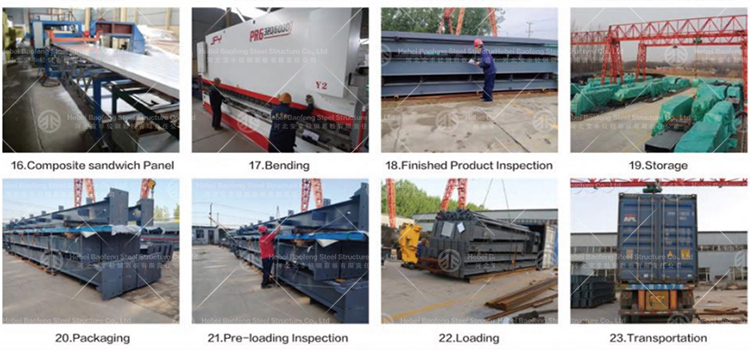

16. Composite sandwich Panel: High-speed production of 2,000 meters daily.

17. Bending: Accessories and gutters for the entire facility are fabricated here.

18. Finished Product Inspection: Goods can not be allowed to be packed until getting the approval by QC Authorities.

19. Storage: Qualified products are categorized and stored in the yard, to keep the goods are clean, dry and ventilated.

20. Packaging: packed with steel crates, save shipping container.

21. Pre-loading Inspection: Quantity and appearance inspections are conducted before loading, ensuring customers can receive the perfect goods.

ADVANTAGES

(1) Free design and architectural drawings provided;

(2) Durability, easy maintenance, designed life span for 50 years;

(3) Fast and easy assemble, online installation guidance provided;

(4) Elaborate and strong design, high wind resistance performance;

(5) Thermal and noise insulation, water proof and fire prevention.

If you need to build steel structure projects, pls contact us.

Previous :

Light steel frame warehouse 2000 square meter hangar price prefab steel structure shedNext :

New fashion metal building with crane light steel structure warehouseIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories