Metal steel structure frame building manufacturer

Item No.:

Gg-135Payment:

T/T & L/CProduct origin:

Hebei, ChinaShipping port:

TianjinLead Time:

about 30 daysPrice:

30-50 usd/sqmProduct Description

|

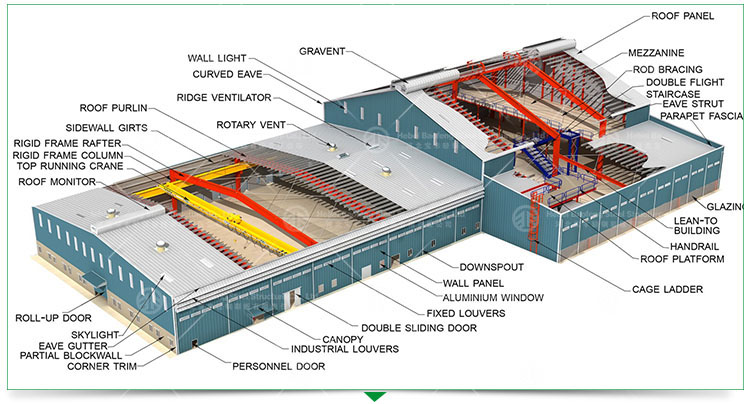

Size |

Customized |

|

Application |

Steel Structure Warehouse/Workshop/Hanger/Shed/ Sports Stadium |

|

Main Frame |

H section steel |

|

Purlin |

C,Z purlin |

|

Roof and Wall Material |

EPS/rock wool/fiberglass wool/PU sandwich panel,corrugated sheet |

|

Surface Treatment |

Hot-dip galvanized,electric galvanization,paint |

|

Colour |

customized |

|

Performance |

Heat-insulation,Fire proof,Sound proof,recyclable |

Production process

1. Pre-production meeting: Discuss project requirements and execution standards, ensuring customer’s demands are accurately forwarded to the production line.

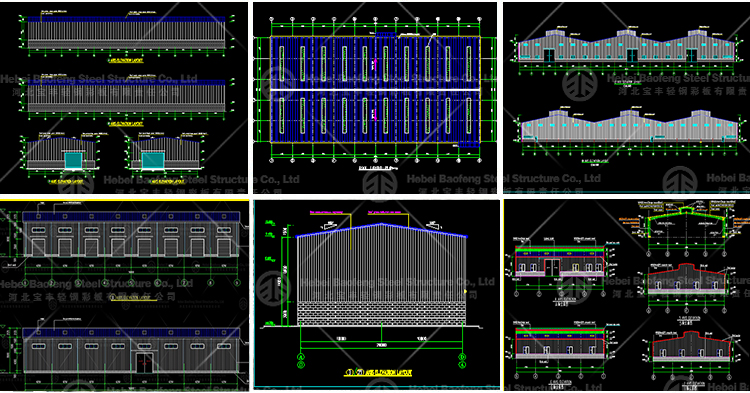

2. Production drawings: With quality requirements and process standards.

3. Raw Material Inspection: Rigorous inspection of raw materials ensures qualified products entering the factory.

4. CNC flame cutting and slicing:High Precision and high production efficiency make the steel cutting amount per day up to 150-200 tons.

5. H-Beam Spot Welding and Assembly: Assembled welded and corrected in a streamlined process with a production rate of approximately 25 meters per hour.

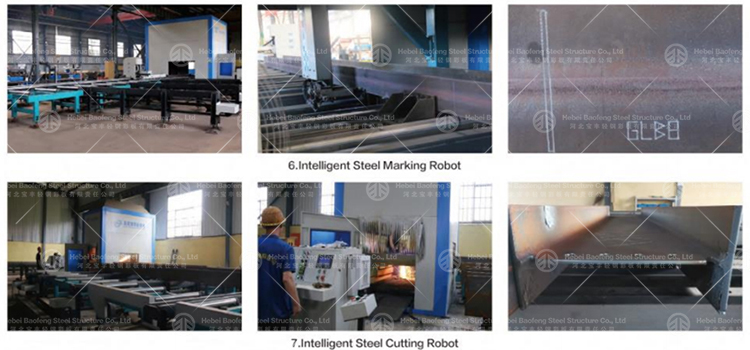

6. Intelligent Steel Marking Robot: Smart operation for precise line marking.

7. Intelligent Steel Cutting Robot: Infrared ray scans marking, accurate cutting. Perfect finish, efficient cuts up to 50 tons.

8. Small Plates Fabrication: Automated CNC machines, ensuring high-speed, accurate drilling to guarantee error-free installation.

9. Assembly: Connected plates are assembled and welded on H beam, Cross work maximize welding efficiency.

10. Shot Blasting: Sa 2.5 grade clean rust and enhance coating adhesion, extend life usage.

11. Semi-Finished Product Inspection: 100% quality inspection to ensure product compliance.

12. Painting: Four coats of paint , ensuring a smooth, bubble-free, crack-free, and uniform surface finish.

13. Product Coding: Every steel structure part is clearly coded according to installation drawings, ensuring smooth installation.

14. C-Steel Production: CNC programming ensure smooth, high-efficiency production, yielding 5,000 meters daily.

15. Single Panel Production: Six machines produce 10,000 meters daily, high efficiency.

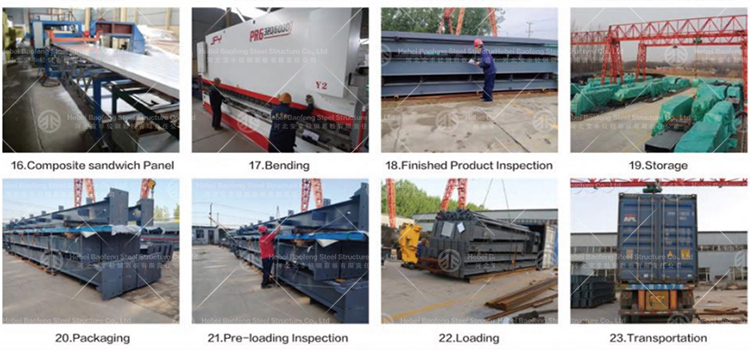

16. Composite sandwich Panel: High-speed production of 2,000 meters daily.

17. Bending: Accessories and gutters for the entire facility are fabricated here.

18. Finished Product Inspection: Goods can not be allowed to be packed until getting the approval by QC Authorities.

19. Storage: Qualified products are categorized and stored in the yard, to keep the goods are clean, dry and ventilated.

20. Packaging: packed with steel crates, save shipping container.

21. Pre-loading Inspection: Quantity and appearance inspections are conducted before loading, ensuring customers can receive the perfect goods.

ADVANTAGES

(1) Free design and architectural drawings provided;

(2) Durability, easy maintenance, designed life span for 50 years;

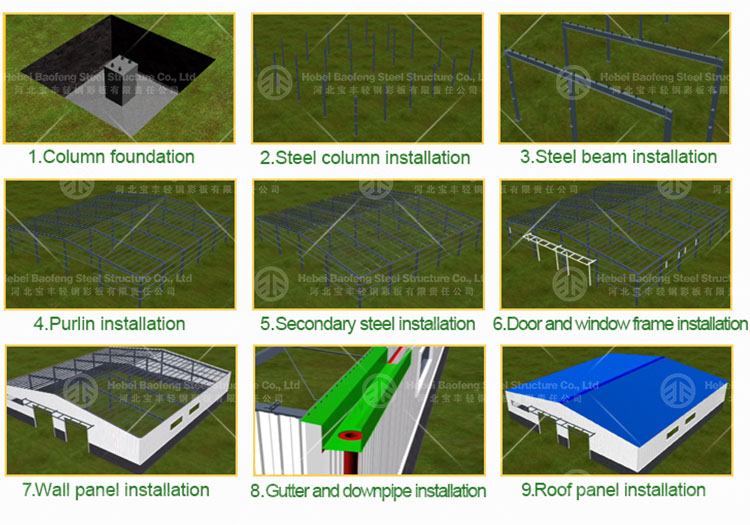

(3) Fast and easy assemble, online installation guidance provided;

(4) Elaborate and strong design, high wind resistance performance;

(5) Thermal and noise insulation, water proof and fire prevention.

If you are looking for your next steel warehouse, then Hebei Baofeng has you covered! We offer prefabricated and customized steel building packages and will work with you to ensure your building design matches your organization’s specific needs.

If you’d like to learn more about available products and services, then feel free to contact us at your convenience. We’re here to answer your questions and help select the optimal steel building design for you. Pls contact us.

Previous :

Warehouse structures low cost steel structure commercial metal building systemsNext :

High quality welded steel structural frame for steel structure buildingsIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories