Prefabricated steel structure broiler, layer hen house

Item No.:

Js-31xgPayment:

T/T, L/CProduct origin:

Hebei,ChinaShipping port:

Tianjin portLead Time:

about 30 daysPrice:

29-39 usd/sqmPrefab steel chicken house characteristics

1. Wide span:single span or multiple spans, the max span is 36m without middle column.

2. Low cost and maintenance: unit price range from USD30/m2 to USD65/m2 according to customers request.

3. Fast construction and easy installation: time saving and labor saving.

4. Long using lifespan: up to 50 years.

5. Nice appearance.

6. Others: environmental protection, stable structure, High quake-proof, water proof and fire proof, and energy conserving.

Prefab Steel Structure Chicken Farm

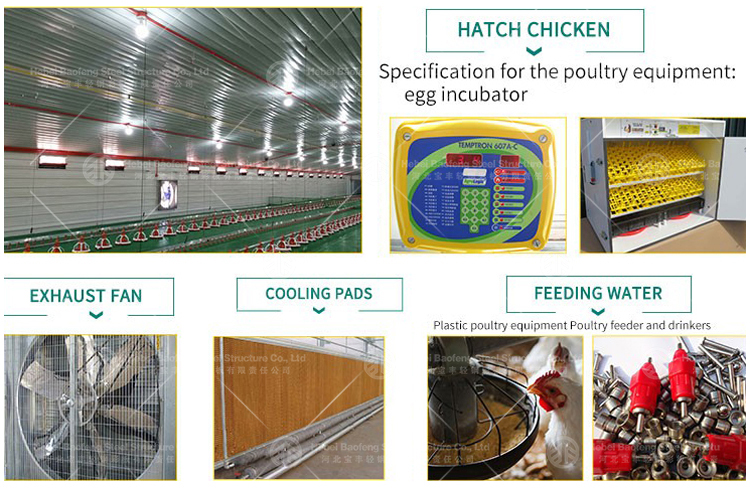

1.Based on the chicken raising type, free range raising and cage raising,the poultry house divided into free range raising type and cage raising type poultry house.

2.15-18 broilers per square meter, 18-20 laying hens per square meter.

| Use | Broiler or layerfarm shed |

| Type |

Closed type or open type |

|

Material |

H-beam/C-beam |

|

Surface treatment |

Galvanized/anti-rust paint |

|

Ventilation |

As customer's needs |

|

Feed type |

With cage or free range |

|

Certification |

CE iso9001 |

|

Brand Name |

BaoFeng |

|

MOQ |

600sqm |

Steel structure production process

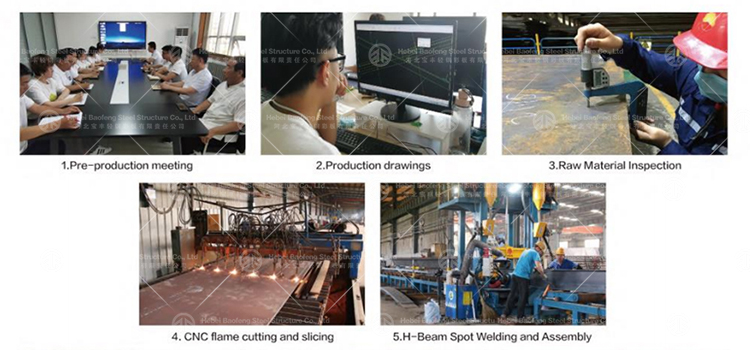

1. Pre-production meeting: Discuss project requirements and execution standards, ensuring customer’s demands are accurately forwarded to the production line.

2. Production drawings: With quality requirements and process standards.

3. Raw Material Inspection: Rigorous inspection of raw materials ensures qualified products entering the factory.

4. CNC flame cutting and slicing:High Precision and high production efficiency make the steel cutting amount per day up to 150-200 tons.

5. H-Beam Spot Welding and Assembly: Assembled welded and corrected in a streamlined process with a production rate of approximately 25 meters per hour.

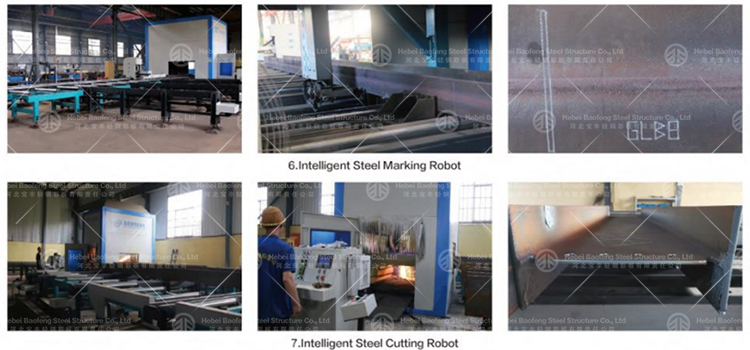

6. Intelligent Steel Marking Robot: Smart operation for precise line marking.

7. Intelligent Steel Cutting Robot: Infrared ray scans marking, accurate cutting. Perfect finish, efficient cuts up to 50 tons.

8. Small Plates Fabrication: Automated CNC machines, ensuring high-speed, accurate drilling to guarantee error-free installation.

9. Assembly: Connected plates are assembled and welded on H beam, Cross work maximize welding efficiency.

10. Shot Blasting: Sa 2.5 grade clean rust and enhance coating adhesion, extend life usage.

11. Semi-Finished Product Inspection: 100% quality inspection to ensure product compliance.

12. Painting: Four coats of paint , ensuring a smooth, bubble-free, crack-free, and uniform surface finish.

13. Product Coding: Every steel structure part is clearly coded according to installation drawings, ensuring smooth installation.

14. C-Steel Production: CNC programming ensure smooth, high-efficiency production, yielding 5,000 meters daily.

15. Single Panel Production: Six machines produce 10,000 meters daily, high efficiency.

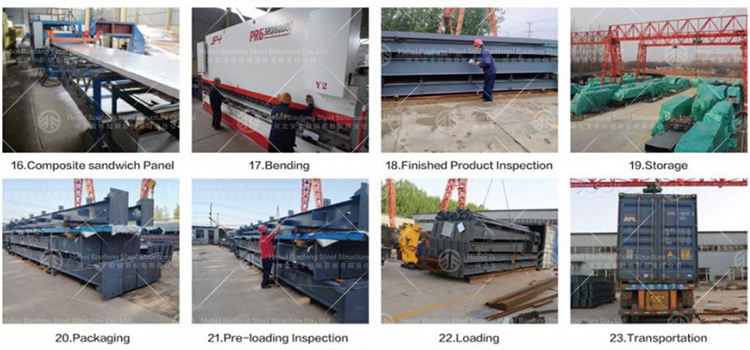

16. Composite sandwich Panel: High-speed production of 2,000 meters daily.

17. Bending: Accessories and gutters for the entire facility are fabricated here.

18. Finished Product Inspection: Goods can not be allowed to be packed until getting the approval by QC Authorities.

19. Storage: Qualified products are categorized and stored in the yard, to keep the goods are clean, dry and ventilated.

20. Packaging: packed with steel crates, save shipping container.

21. Pre-loading Inspection: Quantity and appearance inspections are conducted before loading, ensuring customers can receive the perfect goods.

Company profile

Hebei Baofeng Steel Structure Co., Ltd.is located in Cangzhou City, Hebei Province, 150 kilometers away from Tianjin Port, convenient for transportation.

The company is a professional steel structure manufacturer with 20 years of production experience; it has scientific and advanced technical support and a number of perfect standardized production lines; professional and experienced designers, we will provide you free of charge according to your requirements. Create a unique steel structure design.

If you need it, please answer the following questions so that we can serve you in time:

1>What about the length width and height you need to build?

2>Or how many chickens do you want to raise?boiler or layer?

3>Do you have a drawing of your chicken house?

4>Where is your project site?

Previous :

Prefab large capacity chicken house steel structures farm buildingsNext :

High quality prefab steel structure building chicken farm poultry houseIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories